"sony1492" (sony1492)

"sony1492" (sony1492)

09/25/2020 at 23:59 ē Filed to: locost

11

11

15

15

"sony1492" (sony1492)

"sony1492" (sony1492)

09/25/2020 at 23:59 ē Filed to: locost |  11 11

|  15 15 |

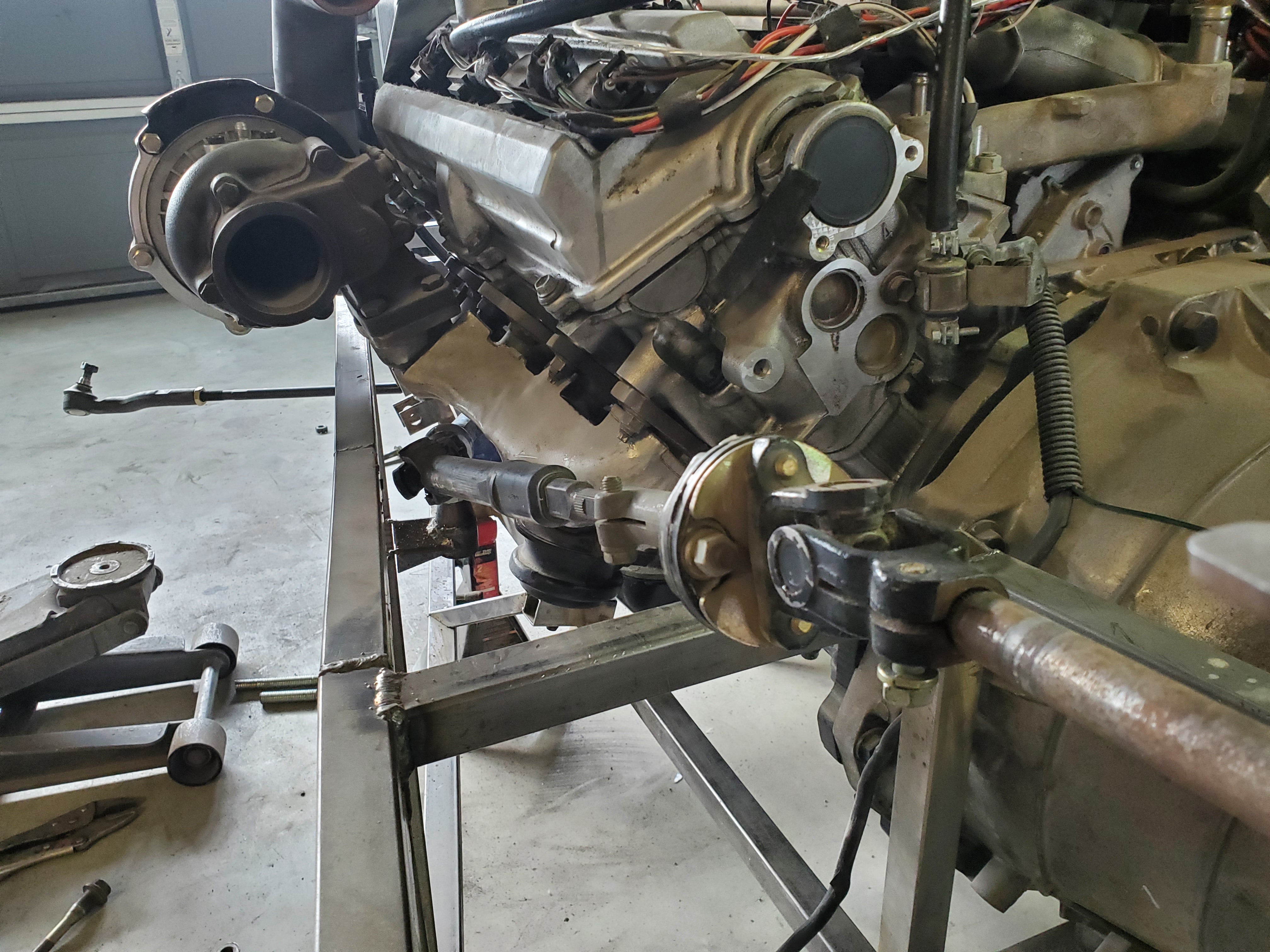

Steering in now functional!

The setup is a shortened sc400 steering rack, ls400 outer tierods,

†91 Celica inner tierods(might switch to 93 Passat for more length), one modified sc400 steering shaft connected to another stock unit, then an sc400 steering column.

Not being skewered by the steering column is pretty high on my list so it uses all stock parts save for lengthening one shaft with tube of the same diameter. The way it ends up snaking around the exhaust manifolds means it aught to fold out in an accident too.

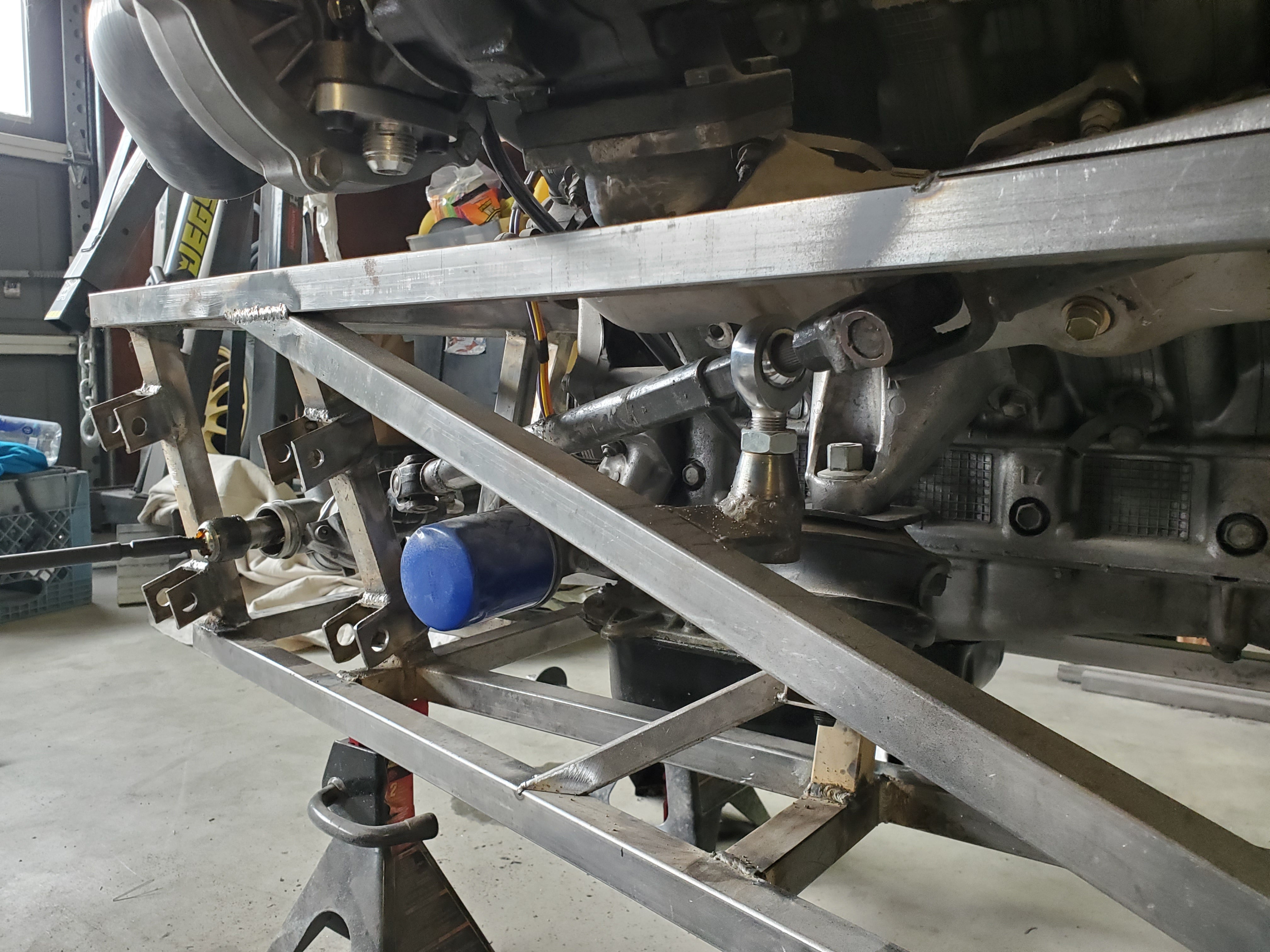

Front suspension is all welded together though the lcas still need shock mounts sorted, after that the Upper arms will get a brace to tie both mounts (the horizontal bar in, A) The steering rack mounts are tacked in place but its offset 1/4" too far left, that needs sorting and welding a third mount on the far end.

The steering column mount was preliminary and its getting scrapped, the steering wheel sits a little too low and at a bad angle. New mount will be 1-2" higher going across to the other side as a brace along with triangulation that isnt nonsense

The time is drawing near to buy a better welder, the welds keep looking poor because the wire feed isnít consistent. I believe the welds are still strong based on parts ive cut out to redo and destructive testing but it would be nice to not work around the equipment.

BaconSandwich is tasty.

> sony1492

BaconSandwich is tasty.

> sony1492

09/26/2020 at 00:21 |

|

Looks like progress to me! It's neat to see things moving along.

sony1492

> BaconSandwich is tasty.

sony1492

> BaconSandwich is tasty.

09/26/2020 at 00:31 |

|

Its good to get back into after a few months, the process of writing t hese posts seems to help organize what needs to be done.†

jminer

> sony1492

jminer

> sony1492

09/26/2020 at 01:22 |

|

Man that is starting to look good.

just-a-scratch

> sony1492

just-a-scratch

> sony1492

09/26/2020 at 01:45 |

|

Good work. Looking forward to seeing more of this.

Nick Has an Exocet

> sony1492

Nick Has an Exocet

> sony1492

09/26/2020 at 02:06 |

|

This is a great project. What kind of welder are you currently using?

just-a-scratch

> sony1492

just-a-scratch

> sony1492

09/26/2020 at 02:20 |

|

That looks like a lot of steering angle at the wheels too.

sony1492

> Nick Has an Exocet

sony1492

> Nick Has an Exocet

09/26/2020 at 02:22 |

|

Century 90amp, †flux core only. It was never designed to do jobs like this, did fine making a gate though.

sony1492

> just-a-scratch

sony1492

> just-a-scratch

09/26/2020 at 02:26 |

|

It is, they are modified from my old sc400 that was setup to slide a bit . The arm coming off the knuckle for the tie rod was shortened and lowered .

Nick Has an Exocet

> sony1492

Nick Has an Exocet

> sony1492

09/26/2020 at 02:31 |

|

They look good to me. I have a crappy Forney Flux .

sony1492

> Nick Has an Exocet

sony1492

> Nick Has an Exocet

09/26/2020 at 02:34 |

|

You can see on the arm how it built up in spots, partly from me but also from the motor slowing.

How did you survive without amp adjustment?!

Nick Has an Exocet

> sony1492

Nick Has an Exocet

> sony1492

09/26/2020 at 02:41 |

|

Itís been challenging. It basically has low and high. You just adjust wire speed and hand

motion to compensate.

My bird IS the word

> sony1492

My bird IS the word

> sony1492

09/26/2020 at 07:50 |

|

The turbo is going to be sticking out of the bodywork? Nice. I'm bummed I had no idea you were working on this project. Currently going on extreme crash savings to buy a caterham in about five years.

sony1492

> My bird IS the word

sony1492

> My bird IS the word

09/26/2020 at 10:08 |

|

Turbos will get some form of tumor to cover them, kinda hate exposed engine bits. The car might get a full closed wheel body though, figuring out how to make buck is an unknown that could be a setback.

5 years is a long time for extreme saving, but you know what you want! You looked at an sv earlier in the year?

My bird IS the word

> sony1492

My bird IS the word

> sony1492

09/26/2020 at 12:16 |

|

Yeah well I also got about 75k in student loans . I did get a test ( ride along ) in a 360 sv this year and absolutely loved it. Iíve wanted something like these since middle school (thanks test drive unlimited) and blah blah live for the moment blah blah death of gas engines blah. Luckily my parents are ok with me living with them as long as I am being somewhat responsible. That five years is paying for alot of other life stuff.

I would almost want something that looked like one of those pro stock hood scoops to cover the turbo vs a blister.

CaptDale - is secretly British

> sony1492

CaptDale - is secretly British

> sony1492

09/27/2020 at 17:24 |

|

YES! Very cool